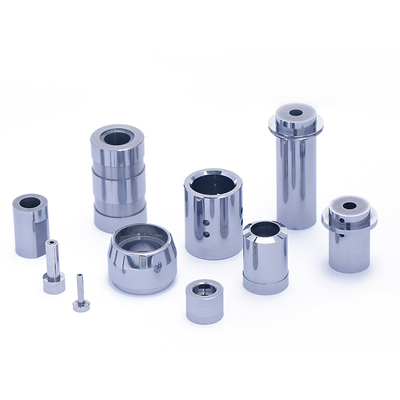

Özelleştirilmiş Zımba Kalıp Bileşenleri Tungsten Karbür Kalıpları Soğuk Şekillendirme Somunları İçin

Ürün Açıklaması

Soğuk şekillendirme somunları ve vidalar için özelleştirilmiş Tungsten Karbür Bağlantı Elemanı Kalıpları. Profesyonel ekibimiz, yüksek kaliteli bağlantı elemanı kalıp üretimine odaklanarak eksiksiz çözümler sunan, bağlantı elemanı endüstrisinde 10 yılı aşkın deneyime sahiptir.

Uygulama Alanı

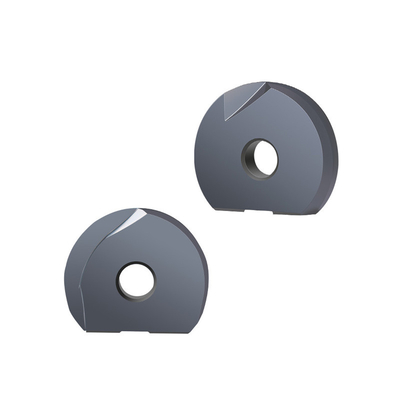

Bağlantı elemanı kalıpları tipik olarak standart parçaların, rulmanların, vidaların ve somunların soğuk şekillendirilmesi ve soğuk zımbalanması için kullanılır.

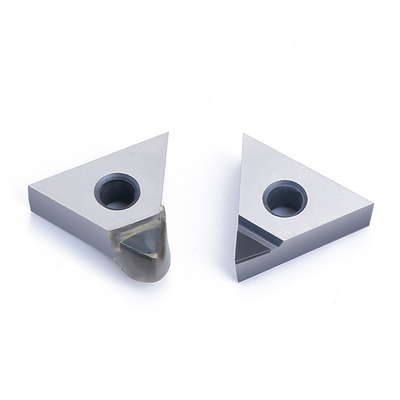

Ürün Detayları - Karbür Çizim Kalıpları

- Yüzey Pürüzlülüğü: RZ~~0.2um / F1.0mm/dak

- Hassasiyet: ±0.001mm

- Özelleştirme: Sadece tamamen özelleştirilmiş üretim - standart stok mevcut değildir. Lütfen sorunuzla birlikte CAD/3D çizimler sağlayın.

Uygun Malzemeler

| Malzeme |

Malzeme Özellikleri |

| Karbür |

Sementit karbür, sert malzeme fazlarından (örneğin tungsten karbür) ve bağlayıcı malzemeden (örneğin kobalt) oluşan bir toz metalurjik kompozittir. Yüksek aşınma direnci ve termal kararlılığa sahip son derece serttir. Kalıp çeliğinden daha zor işlenir ancak önemli ölçüde daha uzun hizmet ömrü sunar. |

| Seramik |

Mükemmel yüksek sıcaklık direnci (180°C ila 1200°C+). Özellikle asit ve alkali çözeltilerde kimyasal saldırılara karşı dayanıklıdır. Yaygın türler arasında alümina, zirkonya, silisyum karbür ve silisyum nitrür seramikleri bulunur. |

| HSS |

Üstün aşınma direnci ve tokluğa sahip yüksek hız çeliği. Çoğunlukla küçük partili üretimde veya yüksek malzeme tokluğu gerektiren uygulamalarda kullanılır. |

İlgili İşleme Teknolojisi

- Silindirik taşlama

- İç dairesel taşlama

- Optik profil taşlama

- Düz taşlama

- Diş açma

- Orta/düşük hızlı tel kesme

- Ayna deşarj işleme

Neden Bizi Seçmelisiniz

- Gelişmiş Teknoloji: Yüksek hassasiyetle karmaşık yüzeyler ve fonksiyonel yapılar oluşturabilir

- Kısa İşleme Süresi: Zamanında teslimatı sağlamak için verimli üretim

- Yüksek Kalite: 0.005-0.001mm'ye kadar hassasiyet

- Gizlilik Sistemi: Müşteri tasarımları için üçlü koruma önlemleri

- Tam Donanımlı: Gelişmiş ekipmanlarla çoklu üretim hatları

- Uygun Maliyetli: Optimal tasarım ve malzeme seçimi ile rekabetçi fiyatlandırma

Kinyet (şimdi Drow ile birleşti), tungsten malzeme Ar-Ge'sine odaklanmakta, yüksek hassasiyetli, uzun ömürlü kalıpları rekabetçi fiyatlarla sağlamak için sürekli olarak yeni teknolojiler sunmakta ve üst düzey ekipmanlara yatırım yapmaktadır.

Kalite Kriterleri

- Aşınma Direnci

- Hassasiyet

- Korozyon Direnci

- Darbe Dayanımı

- Tokluk

- Elastisite/Sertlik Modülü

- Enine Kopma Mukavemeti

SSS

S1: Özel zımba kalıbı veya zımba kalıp bileşenleri üretiyor musunuz?

C: Evet, çeşitli talepkar uygulamalar ve malzemeler için özelleştirilmiş kalıp imalatında uzmanız.

S2: Düşük hacimli numune siparişlerini kabul ediyor musunuz? MOQ'nunuz nedir?

C: Evet, numuneler için bir adet MOQ kabul edilir. Lütfen CAD/3D çizimler sağlayın. Numune teslim süresi 10-15 gündür (özel gereksinimler için pazarlık edilebilir).

S3: Gizliliği nasıl sağlıyorsunuz?

C: Tüm müşteri bilgileri korunmaktadır. Talep üzerine Gizlilik Sözleşmeleri imzalayabiliriz.

S4: Ödeme koşullarınız nelerdir?

C: T/T ile %30 depozito, teslimattan önce %70 bakiye. Nihai ödemeden önce ürün fotoğrafları sağlıyoruz.

S5: Hangi ürünleri sunuyorsunuz?

C: Karbür uçlar, parmak frezeler, matkaplar, delme takımları, kesici takımlar ve özelleştirilmiş hassas kalıplar.

S6: Özel kesme uçları veya takımlar üretiyor musunuz?

C: Evet, çeşitli uygulamalar ve malzemeler için özelleştirilmiş kesici imalatında uzmanız.

S7: Teslimattan önce tüm malları test ediyor musunuz?

C: Evet, ISO9001 standartlarına uygun olarak %100 test yapıyoruz ve sıkı kalite kontrol uyguluyoruz.

S8: Teslimat seçenekleriniz nelerdir?

C: Müşteri gereksinimlerine göre en iyi nakliye hizmetini sağlıyoruz.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!